From Taiwan To The World: The Critical Role Of Supply Chain Logistics In The Semiconductor Industry

By Michael Chu | April 10, 2025

Taiwan plays a starring role in the global semiconductor industry. Critical to this is the semiconductor supply chain, which needs to be reliable and agile enough to withstand disruption, market fluctuations and risks.

- Taiwan is projected to produce 80% of global semiconductors by 2030.

- When it comes to Taiwanese chip exports, fast transportation and real-time tracking are crucial for businesses to maintain a competitive edge in the global market.

- With semiconductor production spanning multiple locations, smart supply chains are essential to ensuring reliable logistics and business continuity.

Driven by the growing demand for AI and High-Performance Computing (HPC), Taiwan’s semiconductor industry is expected to experience significant growth in 2025 and beyond. This growth is already evident, with Taiwan's total semiconductor exports reaching US$165 billion in 2024, according to the Customs Administration of the Republic of China.

Taiwanese companies have built a strong reputation for cutting-edge manufacturing processes, IC design and packaging, especially in advanced process technologies.

According to a report by the Market Intelligence and Consulting Institute (MIC), Taiwan is projected to remain the global hub for semiconductor production through 2030. In fact, Taiwanese manufacturers are expected to account for 80% of global production capacity.

This dominance is driven by the technological expertise and the stability and security Taiwan offers within the global supply chain.

Recent US export control policies, targeting countries like China, have further amplified this trend. As a result, semiconductor companies from the US and other countries have shifted part of their production to Taiwan or formed partnerships with Taiwanese firms. This includes major global tech companies such as Apple, NVIDIA, and Intel.

Despite these shifts, many semiconductor firms in Taiwan have shared plans to keep most of their production onshore, leveraging the island’s mature supply chain and robust talent networks.

However, the industry still faces challenges. Taiwan's relatively low self-sufficiency in materials and equipment poses a potential risk. What’s more, companies are realizing the growing importance of logistics in the overall semiconductor supply chain. Consequently, efficient logistics management is becoming increasingly critical for Taiwanese semiconductor companies.

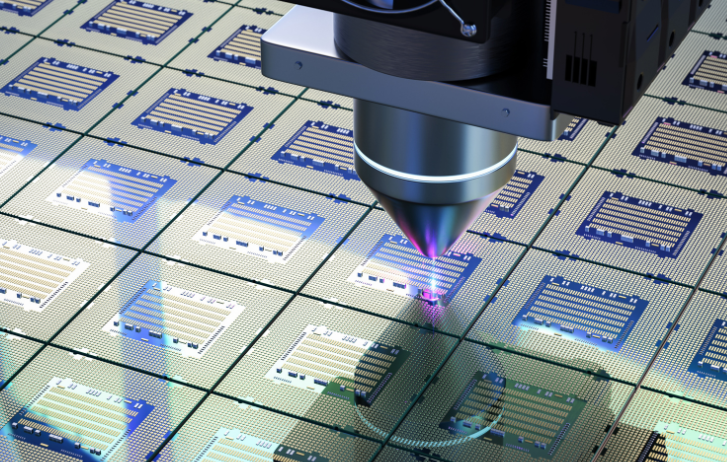

From Taiwan’s factory floors to the world: A cross-border journey for semiconductor chips

Semiconductors rarely follow a direct path from factory to end user. The global supply chain for semiconductor chips is complex. Key stages such as manufacturing, testing, distribution, and delivery take place across different locations.

What does this look like? A chip may start its journey in one country, undergo assembly in another, and pass through several others for quality testing and packaging before reaching its destination.

In response to global supply chain shifts following the US-China trade war and the pandemic, Taiwanese semiconductor companies have accelerated technological advancements and transformed their production models. This includes establishing additional manufacturing facilities in various regions to reduce dependence on any single market or supply chain.

How Taiwan’s semiconductor supply chain can master logistics

In the fast-paced world of semiconductor supply chains, mastering logistics is crucial for maintaining a competitive edge. As semiconductors traverse multiple borders throughout their lifecycle, efficient logistics management becomes a vital component in ensuring the seamless flow of goods.

To streamline semiconductor supply chains, companies must prioritize two key areas: speed and efficiency, and visibility.

1. The race for speed and efficiency in semiconductor logistics

The semiconductor industry is a highly volatile environment, where demand fluctuates rapidly due to market shifts, technological breakthroughs, or changing economic conditions. These fluctuations require ultra-fast transportation solutions to minimize disruption.

Semiconductor shipment delays have cascading effects across many industries where chips are essential for the functionality of end products, such as electronics, automotive, and healthcare. Delays lead to price increases, create imbalances between supply and demand, and further complicate inventory and availability issues.

This means that fast, reliable transportation is critical for meeting production schedules and keeping supply chain operations running smoothly.

2. The power of transparency in semiconductor logistics

Transparency is a fundamental pillar of semiconductor logistics. As the industry becomes more competitive, advanced tracking systems are essential for identifying bottlenecks, delays, or disruptions. Real-time data empowers companies to swiftly resolve issues and adjust production schedules.

Accurate tracking also allows semiconductor companies to forecast demand with greater precision. This helps optimize procurement strategies and supports data-driven distribution planning. Greater visibility fosters a more responsive and agile supply chain, which is critical for staying competitive in a rapidly evolving market.

The trajectory is clear: Taiwan's semiconductor industry is set for continued growth, driven by rising demand for AI, HPC, and other advanced technologies. To maintain its leadership, Taiwan must continue to improve logistics and adapt to the changing demands of the global market to remain agile and competitive.

SHARE THIS STORY

- How To Ship A Giant Panda

- How To Make Freight Shipments Work For Your Small Business

- The Rise Of Intra-Asia Trade: Opportunities In The China-Southeast Asia Corridor

- Southeast Asia: The Next Manufacturing Powerhouse?

- 8 Most Unusual Shipments In The History Of FedEx

- Where Do Old Planes Go When They Retire?

Sign up now and save on your shipping rates!

Sign up now and earn discounts by shipping instantly with FedEx Ship ManagerTM at fedex.com.

Recommended For You

Southeast Asia: The Next Manufacturing Powerhouse?

Vietnam is part of a growing number of production and supply hubs in Southeast Asia. We explore what makes Vietnam successful.

Read More

How New Technologies Deliver Smarter Supply Chains

Emergent technologies like AI are making supply chains smarter, more resilient and agile. We dive deeper into their potential for FedEx and Asia SMEs.

Read More

How To Build Resilient And Reliable Healthcare Supply Chains

Logistics sector leaders are set up to help healthcare providers smooth the pain points in supply chain management in an uncertain world.

Read More