Here's what you'll find on this page:

Here's what you'll

find on this page:

Pallet basics

Pallets are portable platforms used for handling, storing, and shipping products. A pallet provides a sturdy base for stacking multiple items, and it’s constructed to make it easy to move with a forklift or pallet jack.

Did you know? The terms “pallet” and “skid” are often used interchangeably, but there is a subtle difference. A pallet has bottom deck boards, and a skid doesn’t.

Top five considerations when choosing a pallet

Even though pallets are fairly simple, there are still five key factors to consider when you’re choosing a design for your shipment. Keeping these top of mind will help ensure a successful shipment.

1. Strength—Your pallet needs to be strong enough to support the weight of the load it’s carrying throughout storage and shipment. Strength comes from the types of materials you use and the way the pallet is constructed.

2. Stiffness—Pallet materials need to be stiff enough to resist bending and deforming over time. When pallet deck boards start to deform, the integrity and stability of the entire load is compromised. Increasing board thickness or choosing a pallet with an extra stringer (horizontal support board) can increase stiffness.

3. Durability—During shipment, palletized products are usually moved with equipment, stacked under other loads, and faced with environmental fluctuations. Choose a durable pallet with adequate top board spacing so forklift blades will not impact the product.

4. Functionality—The strongest, stiffest, most durable pallet in the world is only useful if it can be moved with standard equipment. Choose a pallet that conforms with industry standards to ensure it can be transported efficiently.

5. Price—You have to find the right balance of cost and quality when choosing a pallet. Consider your budget and the value of the product you’re shipping. If you’ll be receiving the pallet back, it might be worth investing more to have a pallet you can reuse multiple times.

- Typically measure 40" x 48"

- Have four-way entry capabilities

- Can be designed to carry heavy or light loads

- Should be designed to:

- Support the full weight of the packaged product

- Withstand the rigors of the shipping environment

- Ensure adequate top board spacing to avoid forklift blade impact

- Typically more expensive and heavier than wood pallets

- Usually reusable

- Sometimes designed with a solid deck, which protects the package bottom from forklift tine damage during loading and unloading, and helps support the load weight

- Sometimes have a slippery surface, making it hard to fasten or block products

Pallet types we recommend

- Typically measure 40" x 48"

- Have four-way entry capabilities

- Can be designed to carry heavy or light loads

- Should be designed to:

- Support the full weight of the packaged product

- Withstand the rigors of the shipping environment

- Ensure adequate top board spacing to avoid forklift blade impact

- Typically more expensive and heavier than wood pallets

- Usually reusable

- Sometimes designed with a solid deck, which protects the package bottom from forklift tine damage during loading and unloading, and helps support the load weight

- Sometimes have a slippery surface, making it hard to fasten or block products

Corrugated fiberboard pallets

We don’t recommend these pallets because in general they are:

- Easily damaged and especially susceptible to moisture damage

- Often not reusable

Pressed block-style pallets and molded pulp pallets

We don’t recommend these pallets because in general they lack the sturdiness, stiffness, and strength of natural-wood pallets.

Pallet types we don't recommend

Corrugated fiberboard pallets

We don’t recommend these pallets because in general they are:

- Easily damaged and especially susceptible to moisture damage

- Often not reusable

Pressed block-style pallets and molded pulp pallets

We don’t recommend these pallets because in general they lack the sturdiness, stiffness, and strength of natural-wood pallets.

Need more help deciding on the right pallet?

Our customer service team can give you guidance when you’re trying to decide which pallet type is right for you.

- For FedEx Freight® (less-than-truckload [LTL] shipments), call 1.866.393.4585.

- For FedEx Express® Freight (air shipments), call 1.800.332.0807.

Solidify your shipping strategy

.jpg)

.jpg)

.jpg)

- Explore our guidelines to discover more freight packing methods.

Explore our guidelines to discover more freight packing methods.

.jpg)

.jpg)

.jpg)

- Get professional packing tips from our packaging engineers.

Get professional packing tips from our packaging engineers.

- Apply for complimentary package testing to help minimize damage.

Apply for complimentary package testing to help minimize damage.

Freight box options from FedEx

Ready for a simpler freight shipping solution? Consider freight boxes from FedEx. Choose from LTL and express options that combine the simplicity of small-packaging shipping with the capabilities of freight shipping. Talk with your sales rep or speak with an expert to learn more.

How to load your pallet

Carton stacking methods are key to creating a stable load. Here are some tips and guidelines for safe, secure stacking.

Column stack

In this stacking pattern, boxes or cartons are stacked in straight columns with no overlap. In almost all cases, column stacking increases the top-to-bottom compression strength for palletized shipments. Place corrugated pads (load protector pads) between the tiers to increase load stability.

Interlocking stack

If the carton contents are rigid, interlocking cartons can increase stability. If you choose this method, stack boxes corner to corner and edge to edge for more strength.

Stacking methods we recommend

Column stack

In this stacking pattern, boxes or cartons are stacked in straight columns with no overlap. In almost all cases, column stacking increases the top-to-bottom compression strength for palletized shipments. Place corrugated pads (load protector pads) between the tiers to increase load stability.

Interlocking stack

If the carton contents are rigid, interlocking cartons can increase stability. If you choose this method, stack boxes corner to corner and edge to edge for more strength.

Overhanging stack

Never let the products you’re packing overhang the edges of the pallet. This can reduce package compression strength by as much as 32 percent. It can also risk package tears, punctures, and product damage.

Pyramid stack

Stacking palletized loads is common in shipping because it saves space in warehouses and delivery vehicles. Pyramid stacking doesn’t create a level top load surface, so the top-most cartons are at risk of being damaged during stacking.

Stacking methods we don't recommend

Overhanging stack

Never let the products you’re packing overhang the edges of the pallet. This can reduce package compression strength by as much as 32 percent. It can also risk package tears, punctures, and product damage.

Pyramid stack

Stacking palletized loads is common in shipping because it saves space in warehouses and delivery vehicles. Pyramid stacking doesn’t create a level top load surface, so the top-most cartons are at risk of being damaged during stacking.

How to secure your load

Once your products are stacked on the pallet, you need to make sure they stay unitized during shipment. Here are a few of the most common materials you can use to secure your load.

Foam cushioning—Foam density levels vary, so make sure the foam you choose is dense enough to protect your product. It’s a good idea to test the cushioning in an environment that simulates the actual shipping conditions.

Blocking—Use blocking material like wood to prevent any movement when shipping single heavy goods. For items over 1,500 lbs., use hardwood pallets and blocking material, and use at least two fasteners in each brace to prevent pivoting and ensure adequate strength.

Bracing—Items that can roll or shift because of their shape or size should be braced on a forklift-accessible pallet base. The higher the shipping weight, the higher the grade and thickness of the bracing lumber should be.

Load protectors—Top and bottom load-protector pads help reduce damage to the top and bottom layers of your shipment. They also help distribute the weight of top-loaded freight. Bottom load protectors provide a level surface, offer protection from pallet nail heads, and help keep boxes from slipping into the gaps between the boards on the pallet.

Edge boards—Also called angle boards, edge boards should run the full length or depth of the stack to help unitize the load, increase vertical stacking strength, and reduce damage to box edges that make up the load corners.

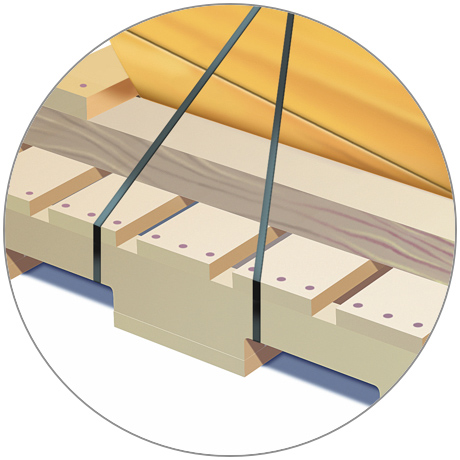

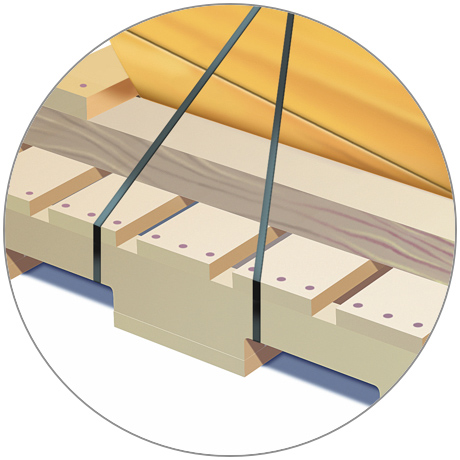

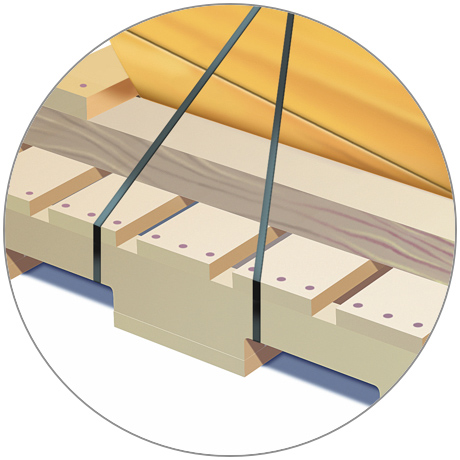

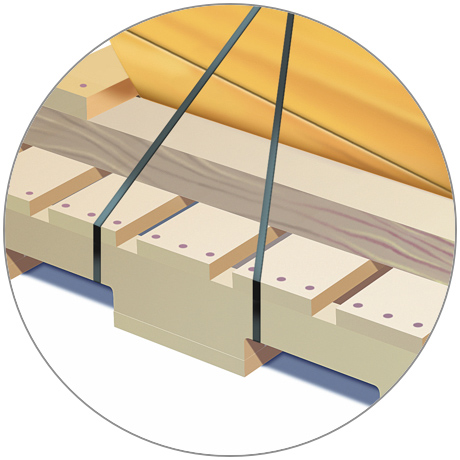

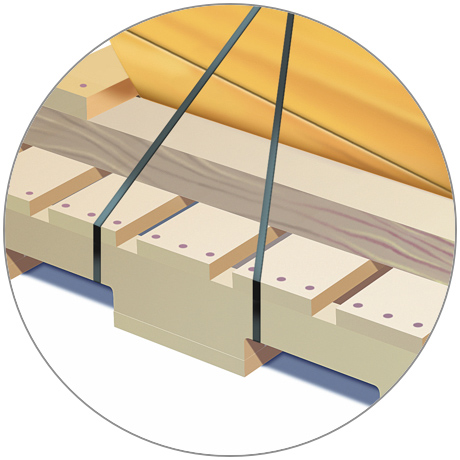

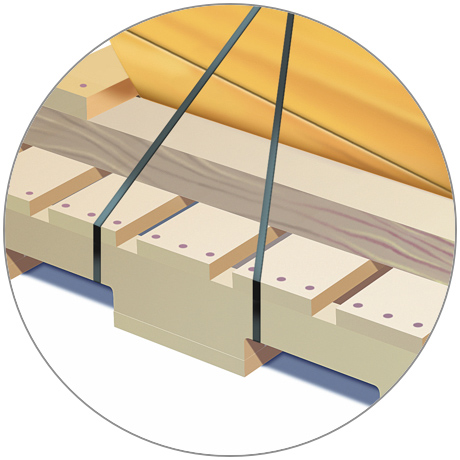

Bands—Banding secures the bundled load to the pallet. Keep the banding close to the load to avoid exposure, damage, or breakage. Loads significantly smaller than the pallet should be centered and banded to the closest pallet deck boards, not the pallet exterior. Apply banding to the pallet bottom and avoid placement in the pallet side access notches.

Stretch wrap—This material is critical for bundling loads and securing and protecting large individual pieces. Wrap loads tightly to prevent shifting. Use 70-gauge stretch wrap that sticks to itself so it can be wipe-sealed as it’s applied. To properly secure the load to the pallet, make sure you’ve achieved the minimum containment force.

How to label your shipment

Labeling your shipment carefully is an easy and important step. It helps handlers move, store, and deliver your shipment successfully. We have a library of the most common labels you might need for shipping freight that you can easily download and print.

Pallets vs. freight boxes vs. crates

The right shipping methods and materials vary based on what you’re shipping and where it’s going. While pallets described above might be the right choice, you might need other materials like freight boxes or shipping crates.

Freight box

A freight box, also called a bulk bin, is a container made of cardboard, wood, plastic, or metal that’s usually attached to a pallet. Get information about using freight boxes for shipments.

Shipping crate

A shipping crate is a heavy-duty shipping container with built-in bracing. Crates are usually made of wood, but can also be metal or plastic. Get information about using shipping crates for shipments.

More freight shipping resources

Answers to your freight pallet questions

A standard pallet is 48" long and 40" wide. The next most common sizes are 42" x 42" and 48" x 48". We recommend the 40" x 48" Grocery Manufacturers Association (GMA) pallet. (This is also called the Consumer Brands Association or CBA pallet.)

Pallet prices vary depending on their size, what they’re made of, and the quality of the construction. If you need help choosing a pallet that’s right for your product, business, and transit scenario, contact our customer support team.

- For FedEx Freight (less-than-truckload [LTL] shipments), call 1.866.393.4585.

- For FedEx Express Freight (air shipments), call 1.800.332.0807.

No, we don't sell traditional pallets, but we do offer freight boxes in two sizes and configurations. One includes an incorporated pallet. Find out more about the FedEx Freight box or contact customer support for guidance on it and other shipping materials, including pallets.

The answer depends on what you’re shipping, the size of your pallet, and your stacking configuration. Start by choosing a pallet that can support the weight of your shipment. Make sure the load doesn’t overhang or sit inboard of the pallet edges, since both of these scenarios can risk product damage. You can also do a web search for “pallet load calculator” to find helpful online tools.

The answer depends on what you’re shipping, where the shipment is originating, where it’s going, how much it weighs, and so much more. Visit our freight shipping calculator for tools to help you calculate your freight shipping rates.

What are the most common pallet sizes?

A standard pallet is 48" long and 40" wide. The next most common sizes are 42" x 42" and 48" x 48". We recommend the 40" x 48" Grocery Manufacturers Association (GMA) pallet. (This is also called the Consumer Brands Association or CBA pallet.)

How much do shipping pallets cost?

Pallet prices vary depending on their size, what they’re made of, and the quality of the construction. If you need help choosing a pallet that’s right for your product, business, and transit scenario, contact our customer support team.

- For FedEx Freight (less-than-truckload [LTL] shipments), call 1.866.393.4585.

- For FedEx Express Freight (air shipments), call 1.800.332.0807.

How can I find or buy shipping pallets? Does FedEx sell traditional pallets?

No, we don't sell traditional pallets, but we do offer freight boxes in two sizes and configurations. One includes an incorporated pallet. Find out more about the FedEx Freight box or contact customer support for guidance on it and other shipping materials, including pallets.

How many boxes fit on a pallet?

The answer depends on what you’re shipping, the size of your pallet, and your stacking configuration. Start by choosing a pallet that can support the weight of your shipment. Make sure the load doesn’t overhang or sit inboard of the pallet edges, since both of these scenarios can risk product damage. You can also do a web search for “pallet load calculator” to find helpful online tools.

How much does shipping a pallet of freight cost?

The answer depends on what you’re shipping, where the shipment is originating, where it’s going, how much it weighs, and so much more. Visit our freight shipping calculator for tools to help you calculate your freight shipping rates.