How to ship automotive

Responsible packaging can save you money and improve the safety and handling of your shipments. Follow these tips and design recommendations.

Steps for how to ship automotive parts

Here's a helpful hint: When packing parts, use adequate packing material such as loosefill peanuts or other padding material to fill void spaces and prevent movement inside the box. When preparing irregular-shaped parts for shipment, tape cushioning material securely to help prevent removal during the handling process.

1. Pad and secure in a corrugated box

Wheels

Cushion the entire surface, and box chrome, painted and decorative wheels that are susceptible to damage as a result of scratches or scuffing. Wrap non-decorative wheels in adequately taped clear plastic liner.

Flexplates, Flywheels

Pack flexplates and flywheels with adequate packing materials such as loosefill peanuts to fill empty spaces in double or triple-wall corrugated boxes, depending on the weight of the part. Apply “heavy” stickers to boxes exceeding 75 lbs.

Car Doors, Hoods, Panels

Cushion and box all exposed metallic surfaces that are susceptible to damage as a result of scratches or dents.

Flexible Plastic Moldings

Cushion and box all flexible plastic moldings to prevent breakage or tearing.

Shocks, Coil Springs

Box cylindrical parts that can be packaged in tubes with adequate dunnage such as padding at the ends and loosefill peanuts to prevent puncturing through the end closures. Tag coil springs with a FedEx nonconveyable tie-on tag and adhere the shipping label to the tie-on tag if the item cannot be packaged in a tube or corrugated box.

Bumpers

Box bumpers that are susceptible to scratches or dents. Or wrap bumpers in adequately taped heavy-duty plastic bags and padding to protect any sharp or pointed corners.

Transmissions

Drain the transmission of all fluids and place it in a plastic bag with absorbent padding below to absorb any residual fluid. When using expendable packaging, securely band it to its pallet, or block or brace it inside its corrugated container. If you use a reusable container, secure the transmission to the base with strapping.

All forkliftable bases for engines and transmissions must be shipped only by FedEx Express® Freight or FedEx Freight services.

Moldings

Wrap non-decorative plastic moldings in adequately taped plastic film or bags, or cushion and box them.

Sway Bars, A-Arms

Wrap sway bars, A-arms and threaded rods in fiberboard or appropriate plastic film or bags and tape securely.

Exhaust System Parts, Leaf Springs

Pad and cover pointed and sharp edges with corrugated boards, adequate foam or air-cellular cushioning material such as Bubble Wrap® and tape securely.

Tires

Place the tire/crate label on the tread of the tire and apply the FedEx shipping label on top of the tire/crate label.

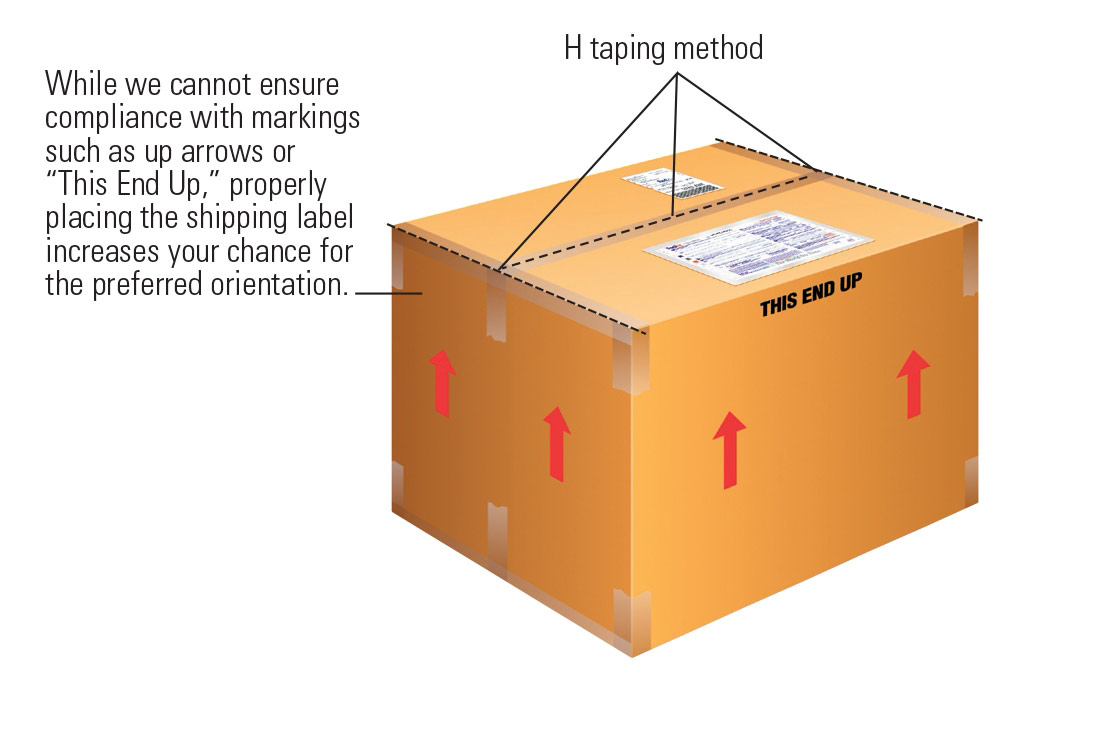

2. Seal and label the package

Using the H tape method, apply at least three strips of pressure-sensitive adhesive plastic tape that is at least 2" wide to both the top and bottom of the carton to protect the package and its contents. Tape all seams or flaps.

When shipping parts that cannot be packaged in corrugated outer containers, tag them appropriately. Tag wrapped and padded parts with a FedEx nonconveyable tie-on tag and adhere the shipping label to the tie-on tag. Request tie-on tags, cable ties or tire/crate labels at fedex.com or call 1.800.GoFedEx 1.800.463.3339.

General guidelines for shipping automotive parts

You are responsible for proper packaging when shipping; these tips should be helpful when packaging specific items. If items are not fully encased in an outside shipping container, an additional handling surcharge may apply.

Parts weighing more than 150 lbs

Secure transmissions and other parts weighing more than 150 lbs. to a forkliftable base compatible for pallet-jack usage. Banding to a pallet or bracing inside a corrugated container helps prevent damage in handling.

FedEx may reject any parts packaging that does not meet the minimum shipping standards for acceptance.

General guidlines

- Pad all sharp edges, corners and burrs of parts such as sheet metal or bare metal.

- Pad or cover precision-machined areas of parts, such as threads and fittings.

- Protect all parts that are susceptible to damage due to dents, scratches and scuffing by using an appropriateamount of cushioning material and placing in a sturdy shipping container.

- Place documentation and shipping or routing labels on flat surfaces that will allow for maximum adhesion. Avoid placing labels around curved surfaces.

- Place all labels on the side with the largest surface area.

- Use FedEx tie-on tags, tire/crate labels or plastic airbill pouches instead of wire tags. FedEx tie-on tags are available at fedex.com or by calling your local FedEx Customer Service.

Automotive Parts Best Practices

- Drain and empty parts filled with lubricant fluids before shipping or demonstrate that the shipment is leakproof under all orientations.

- Help reduce damages and ensure safe working conditions for handlers by adequately packaging all mechanical or automotive parts.

Dangerous goods/hazardous materials guidelines

Some of the most frequently shipped automotive and mechanical parts and accessories may be considered dangerous goods and hazardous materials. These include airbags, aerosols (some examples include paint and lubricants), batteries, engines and engine blocks with hazardous fuel, used fuel tanks, flammable paints, and touch-up paints.

Check with the manufacturer for the Material Safety Data Sheet (MSDS) for detailed information on the product. The shipper is responsible for correctly identifying, classifying, packaging, marking, labeling and completing documentation for dangerous goods and hazardous materials. The Department of Transportation (DOT)/Federal Aviation Administration (FAA) require shippers to have job-specific dangerous goods training prior to tendering dangerous goods to FedEx or another air carrier. Reference the 49 Code of Federal Regulations (49 CFR) 172.700 for complete details.

FedEx Express is required by law to report improperly declared or undeclared shipments of dangerous goods to the DOT. The shipper may be subject to fines and penalties under applicable law. Questions may be directed to the FedEx Dangerous Goods/Hazardous Materials Hotline, 1.800.GoFedEx 1.800.463.3339 (say “dangerous goods”).

Packaging freight shipments

Shipments that qualify as freight must be packaged accordingly. See the current FedEx Service Guide to determine if your shipment qualifies as freight.

You must package your freight shipments to allow for stacking of other packages on top of your shipment. Make sure your freight shipments are banded and stretchwrapped to the pallet, with the bands running in both directions. (Pallet loads secured with only stretchwrap are not acceptable.)

Avoid corrugated pallets or wood pallets without bottom boards. You must secure all freight shipments weighing 151 lbs. or more on a forkliftable base, compatible for pallet-jack usage. The minimum specifications for a typical base for forklift or pallet-jack configuration are illustrated here.

NOTICE: This packaging information is provided to FedEx customers to help reduce loss or damage due to improper packaging. It is NOT intended to be a comprehensive guide for packaging items we accept for transit. We make no warranties, expressed or implied, regarding this information. Proper packaging is the sole responsibility of the shipper. For more information and comprehensive guidelines, contact the FedEx Dangerous Goods/Hazardous Materials Hotline at 1.800.GoFedEx 1.800.463.3339; press “81” or say “dangerous goods,” then press “4” for the next available dangerous goods agent. (Outside the U.S., request to speak to a dangerous goods representative.) Refer to the current FedEx Service Guide for terms, conditions, and limitations applicable to FedEx® delivery services.